HENGYE products series

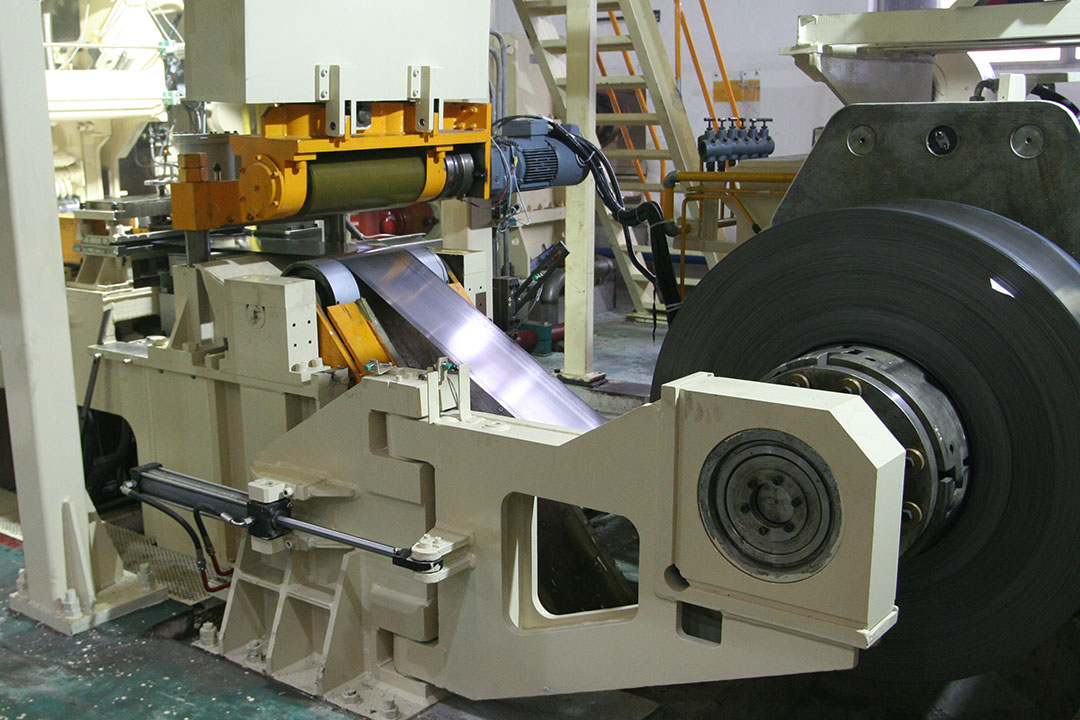

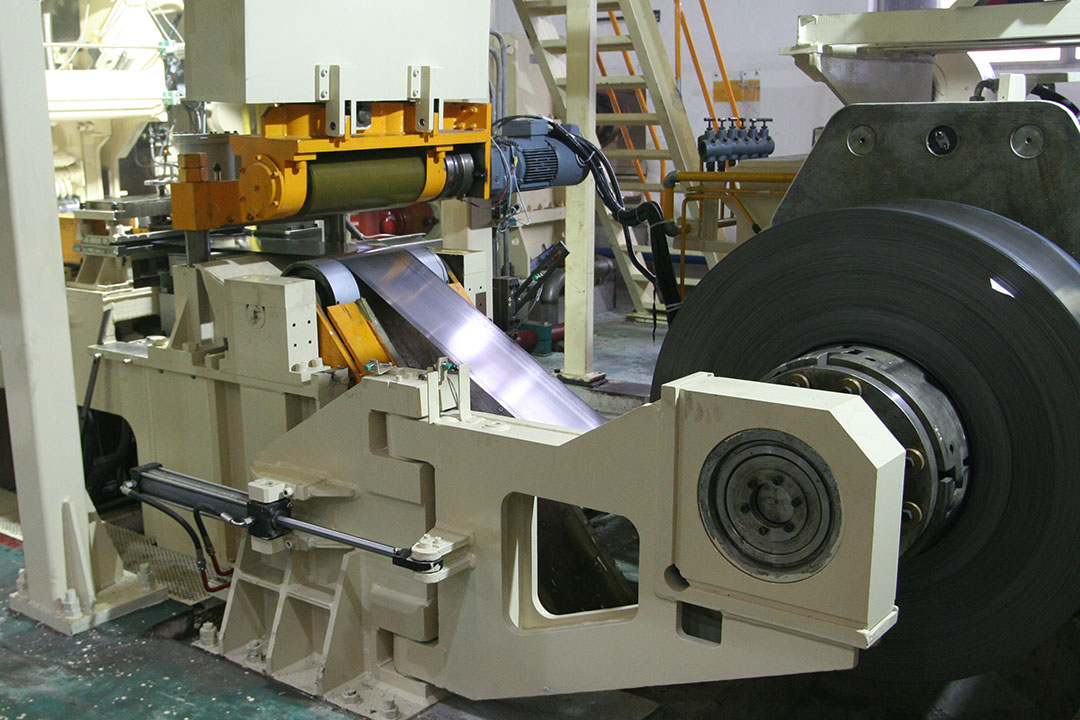

Cold Rolled Steel Strip

First-rate products can let our customers cope with the market competition. Since the establishment of our company, we have set it as our goal. Viewing of the foresight on business & creative management, we always can find a way to stay on top.

The customers' requirements can be efficiently guaranteed with the logistical support & modern technology, which are contributed by our staffs with sense of duty. By the development in recent years, we have become one of the most important suppliers of cold rolled steel material in China. All staffs have been responsibly working to grant our customers best service & convenience, in a wish to develop the fair & mutual co-operation with counterparts.

Product Parameter

Qualities

| Commercial |

|

- St 2-St 4 to DIN 1624 / DIN EN 10139

- or special grades

- IF quality to SEW 095 / DIN EN 10139

|

|

Heat treatable |

|

- C 22-C 60

- CK 22-CK 60

- 38 Cr2-41Cr4

- 25CrMo4-42CrMo4

- 50CrV4 to DIN 17200/DIN EN 10132, part 3

|

|

| Cold rolled wide coil |

|

- St 12-St 14 to DIN 1623, part 1/DIN EN 10130

- or special grades

|

|

Spring steel |

|

- C 55-C 75

- CK 55-CK 75 to DIN 17222/DIN EN 10132, part 4

|

|

| Constructional |

|

- St37 -St70 to DIN 1623,part 2

|

|

High strength low alloy |

|

- ZSTE 260-ZSTE 420 to SEW 093/DIN EN 10268

- ZE 380-ZE 800/special grades similar to SEW 093/DIN EN 10268

- steel with high strength on demand

|

|

| Case hardening |

|

- C 10-C 15

- CK 10-CK15

- 15 Cr3

- 16MnCr5-20MnCr5

- 20MoCr4 to DIN 17200/DIN EN 10132/part 2

|

|

Electrical |

|

- semi finished qualities to DIN 46400, part2/DIN EN 10126

|

|

Enamelling |

|

- EK2-EK4 to DIN 1623 part 3/DIN EN 10209

|

Sizes and weights

| thickness |

|

0,40-5,00mm |

|

width |

|

10-650mm |

|

| coils |

|

up to 20 kg/mm of width |

|

cut to length |

|

450-5,100mm lengths |

|

| traverse wound |

|

up to 30mm of width and max.3,500 kgs coils. |

Tolerances

- to DIN 1544/DIN EN 10140

- to DIN 1541/DIN EN 10131

- normal,fine and precision tolerances or by arrangement

|

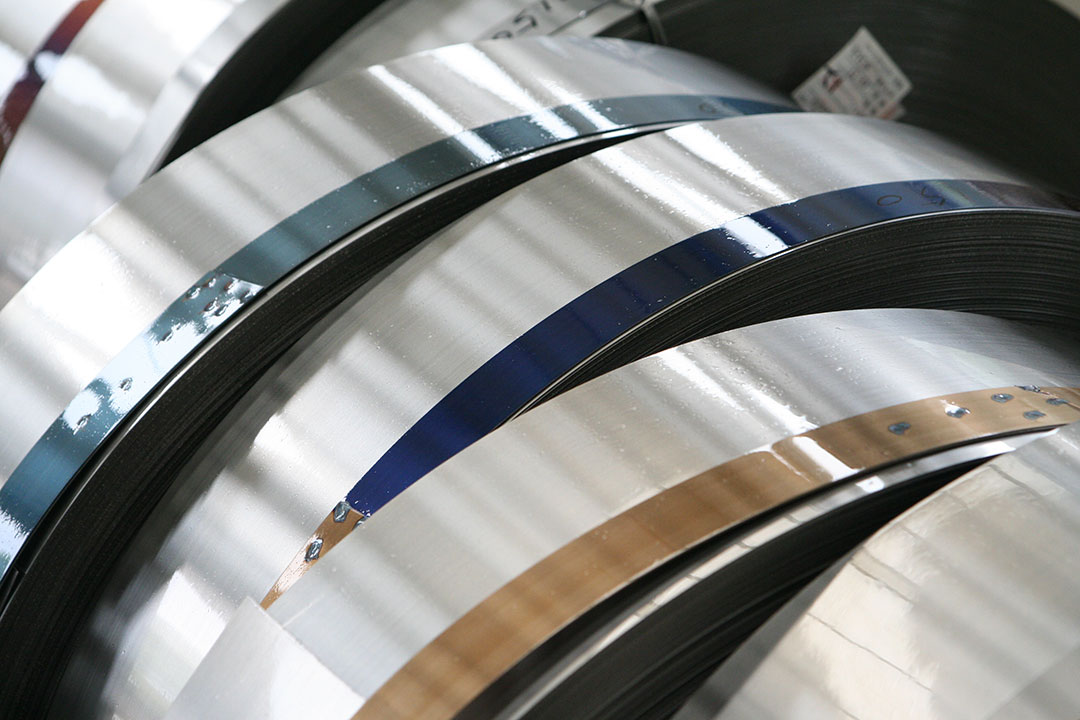

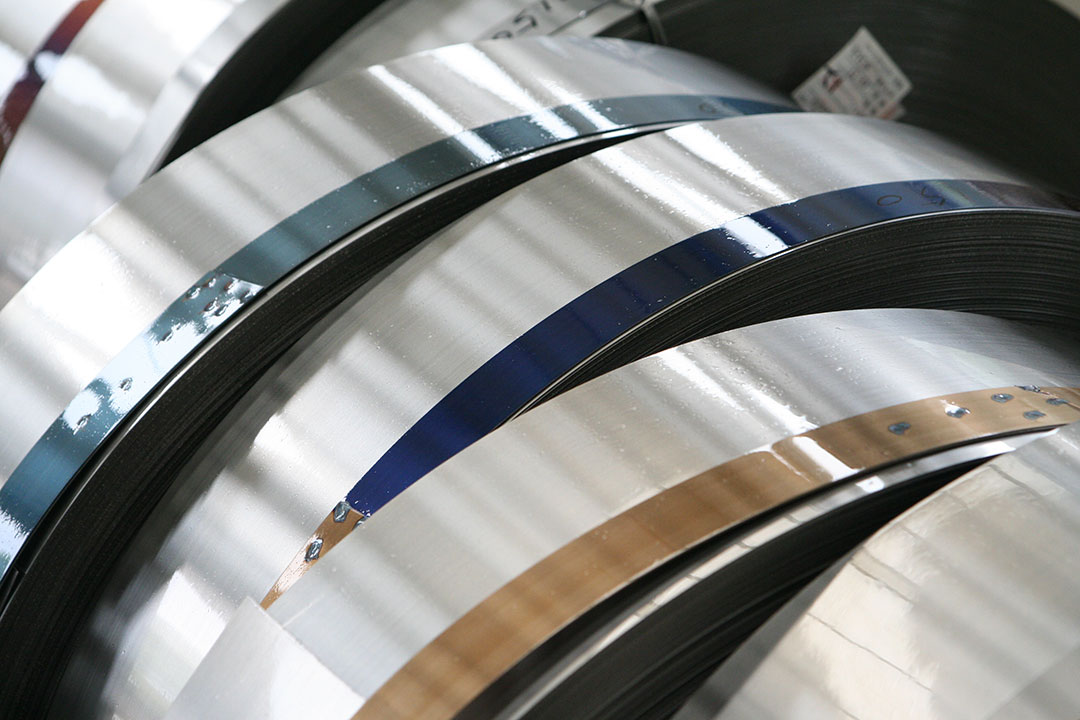

Surfaces

| Types of surfaces to DIN 1624/ DIN EN 10139 |

|

| normal bright |

|

BK/MA |

|

scratch and pit-free |

|

RP/MB |

|

| scratch and pit-free bright |

|

RPG/MC |

Cold rolled steel strip Parameter

| Conditions |

|

- Annealed eventually

- Annealed & Surface is to be smoothly grinded.

- Hardened & Cold Grinded

|

|

Size & Weight |

|

- Length to be cut off:≤20kg/mm Width,1,000~4,000mm Length

- ≤ 30mm Lateral winding

|

|

| Surface |

|

- Medium Brightness

- No scratch or hollow

- No scratch,hollow & brightness

|

|

Edge treatment |

|

- Rolled edge

- Cut edge

- Specially processed edge

|

Application Example

Knitting Machine Needle

Requirements on Steel Material:

- No removal of carbon on the surface.

- Fine-grained sphere treated with carbon.

- Accurate thickness tolerance

- Smooth surface,zero value.

Friction clutch spring

Material feature:

- Be careful to anneal & grind,

- Ensure few burs to break off easily.

- Accurate thickness tolerance

- Minimum bent on lateral direction